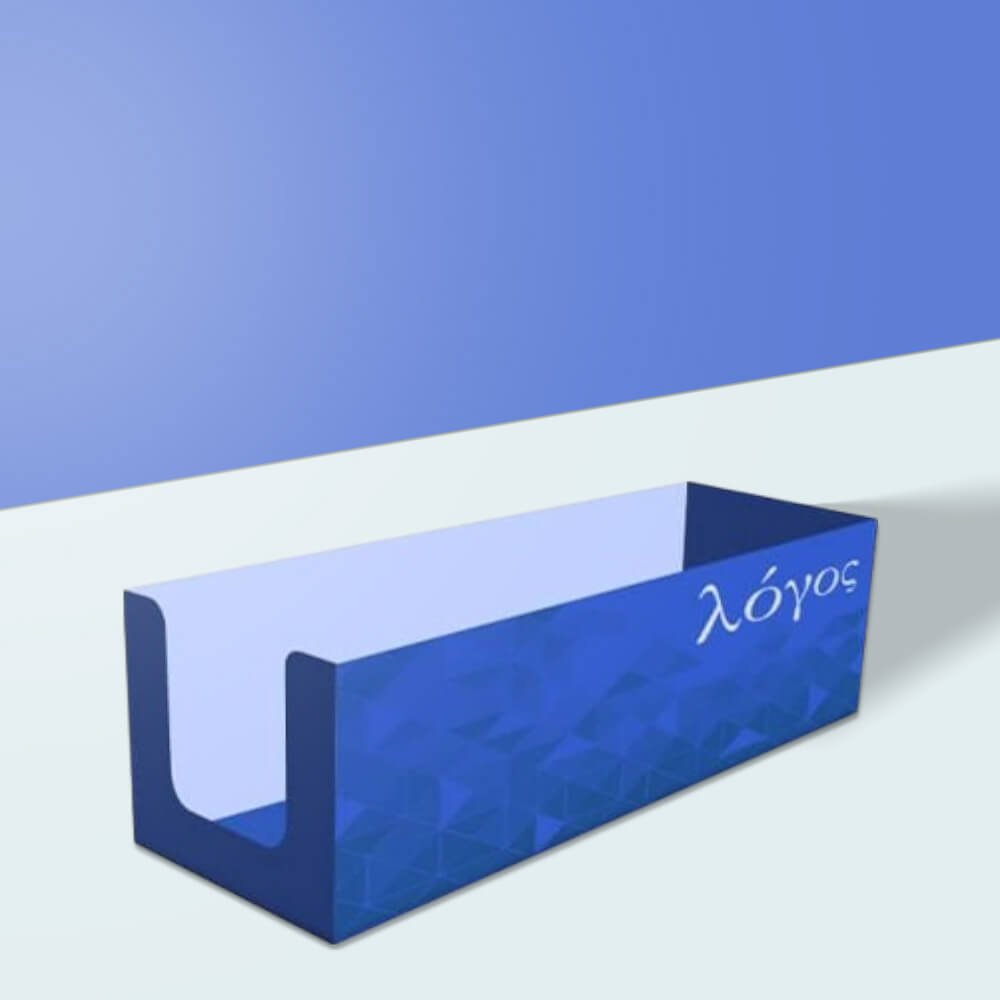

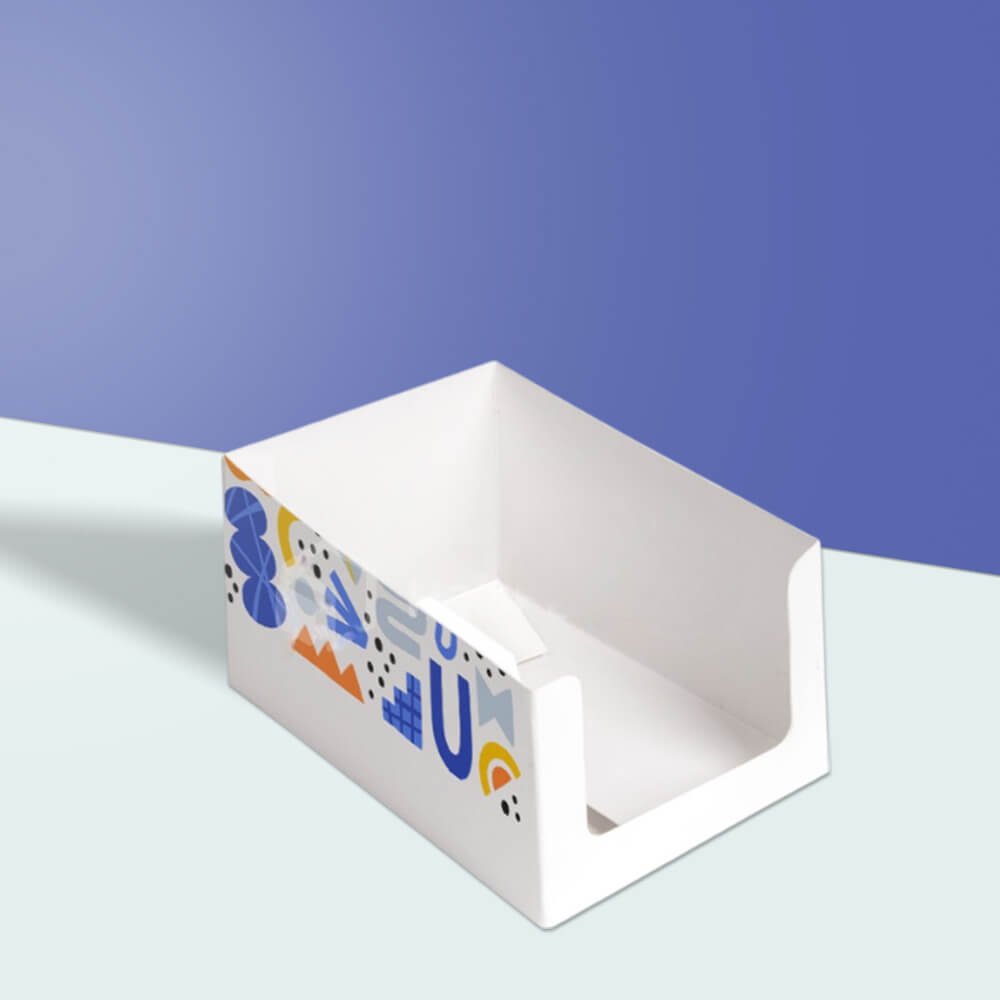

Custom Front Cut out Display Tray

Front cut-out display trays are specialized packaging solutions designed to showcase products prominently in retail settings. These front cut out display tray for packaging feature a die-cut front that allows easy access for customers. It helps in enhancing your product visibility and encouraging sales. These printed front cut out display packaging trays have endless customization options from design to custom sizes, printing to finishing, add-ons to custom sizes, and more. If this is the first time we are collaborating, you can avail massive discounts up to 50% on your first order. Why not get in touch with Eric Warner from our customer support to get a custom front cut out display try at wholesale prices? So, when are you collaborating with the best custom display tray manufacturer in the United States?

Design Support

Get the benefits of our free design support to design a trendy and inspiring box template.

Customization

Customize your boxes in any shape, style, size, coatings, finishes, and printing of your choice.

Sustainability

Promoting sustainable packaging solutions all across the USA to help you go long and go green.

Free Shipping

Offering free shipping with fast turnaround time on both small and bulk orders of custom boxes.

Showcase Your Products Through Front Cut Out Tray For Display

Front cut out counter display tray can be used to pack and showcase different types of products such as:- Toys

- Gift products

- Cosmetics

- Nutritional bars

- CBD products

- Herbs

- Others

Available Materials For Cut Out Display Tray

Choosing the appropriate material for your front cut out tray for display is one of the most important decisions. Remember Most businesses get confused when choosing the appropriate material for their trays. That is why we offer a wide range of materials such as cardboard, kraft, corrugated and more. For your better understanding let’s have a quick discussion on available materials.Front Cut Out Cardboard Display Trays - Affordable

Cardboard is a stiff, paper-based material used for making display trays. It is affordable, flexible, and can be designed in any shape and size you desire. So. If you are a retail seller who is looking for affordable front cut out cardboard display packaging then choosing a cardboard material might be a wise decision for you. Another reason why cardboard is popular among retail businesses is that it is compatible with almost all printing and finishing options. This allows retail businesses to design their custom display trays with front cut out the way they desire without any limitations. The material that we use for cardboard display trays are:- SBS C1S: White paper coated on one side. Good for printing and packaging.

Front Cut Out Kraft Display Trays - Helps To Promote Sustainability

Nowadays customers are getting more concerned about environmental related issues. They have stopped expecting and started demanding brands to do something for the environment. About 82% of consumers across various demographics are willing to pay more for sustainable packaging. Some customers and consumers have gone to the extent that they have stopped purchasing from businesses that sell their goods in plastic packaging. Now being the client of Packlim which is the best sustainable packaging company in the USA we do not want you to miss a potential customer and that is why we offer eco-friendly front cut out display trays. These sustainable cut out display trays are made up of eco-friendly material which is kraft. Kraft paper is made from wood pulp, which comes from trees. There are different types of kraft paper that can be used to make these trays such as:- Natural Brown Kraft: Eco-friendly, strong, versatile paper for tray needs

- Uncoated Unbleached Kraft: Raw, natural look with high-strength properties

- Clay Natural Kraft: Natural look with improved printability and smoothness

Front Cut Out Corrugated Display Trays

Corrugated is a material with parallel folds or ridges. They provide structural support and provide excellent cushioning to delicate items. Corrugated stock is made from wood pulp, and you can recycle it after use.- Kraft Corrugated: Kraft corrugated board employs brown kraft paper for strength.

- E-Flute: Thin, space-efficient packaging for consumer goods.

Custom Sizes To Ensure Proper Product Fit

Each product comes in different sizes and each product requires a unique tray size that is specially designed for it. Traditional display come in limited sizes. But not anymore. To help businesses find the appropriate trays for displaying their products we offer front cut out display trays. These trays with custom logos are specially designed according to your needs and requirements. Now you can rest assured that your products will properly fit inside these trays. So, whether you want small front cut out display trays or large cut out display trays we have you covered.Grab Customer's Eyeballs Through Our Best Custom Front Cut Out Display Tray Designs & Templates

Over 63% of consumers are inclined to purchase products with unique and attractive packaging designs. This is what distinguishes custom display trays from pre-made trays. At Packlim, we turn your ideas into reality. To make it possible we have an in-house team of experienced graphics and packaging designers. By collaborating with them you can be rest assured that your cut out display tray packaging design will stand out on the shelf. Wait what? You don’t have a custom front cut out counter display tray design ready? Do not worry because we also offer creative or modern tray design templates. These templates have been made by our in-house graphic designers. And Guest what, it's free for our clients.Communicate With Your Customers With Our High-Quality Printing

Printing is directly responsible for communicating your brand message with your customers. This is where you can’t mess up. To offer you complete flexibility we offer different printing techniques for our custom printed front cut out trays for display. High-resolution printing of the packaging needs immense expertise. Packlim is the leading printing and packaging services provider in the USA. We offer a range of top-notch printing options to help you design your tray with your desired colors, graphics, product themes, and finishes. Some of our best printing techniques are:- Offset Printing

- Digital Printing

- Screen Printing

- UV Printing

- Offset for bulk orders

- Digital for samples ( less than 100 trays )

- Water-based ink

- Soy/Vegetable ink

- Oil-based ink

- Others

Luxury Finishing Options For Our Custom Front Cut Out Display Tray

One of the easiest ways through which you can capture shoppers' attention is by choosing a unique finishing option for your custom display trays with front cut out. Well, this is where we can help you because our trays come with different finishing options such as:- UV Coating

- Spot Gloss UV

- Soft Touch Coating

- Varnish Coating

- Anti-Scratch Lamination

Stand Out On The Shelf By Choosing The Right Add-Ons

Add-ons add an extra layer of elegance to your trays. This is what helps you to make your products stand out on the shelf. To offer you complete flexibility we offer multiple add-ons such as:- Hot Foil Stamping

- Debossing

- Embossing

- Inserts

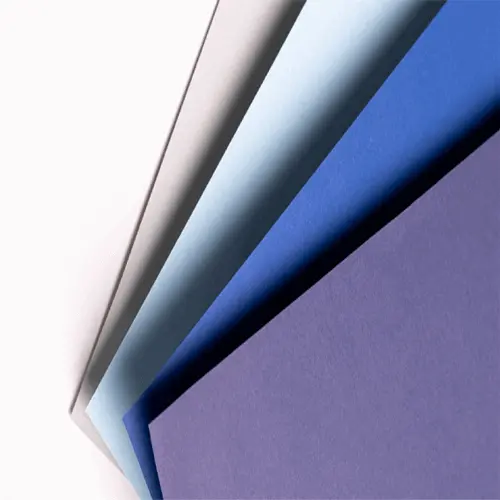

Give Your Products A Classic Look With Our Single Color Front Cut Out Display Trays

Following are the common single-color trays that are used to pack different items.- Front Cut Out Display Black Trays

- Front Cut Out Display Blue Trays

- Front Cut Out Display Green Trays

- Front Cut Out Display Red Trays

- Front Cut Out Display Gray Trays

- Front Cut Out Display Brown Trays

- Front Cut Out Display Gold Trays

- Front Cut Out Display Yellow Trays

- Front Cut Out Display White Trays

- Front Cut Out Display Beige Trays

- Front Cut Out Display Teal Trays

- Front Cut Out Display Silver Trays

Packlim Gives 100% Quality Assurance Guaranteed

Finding a custom box supply company that is consistent with their tray quality is hard. To ensure our clients are getting the maximum return on their investment we have set up a quality assurance department. The prime responsibility of this department is to check each tray manually and if they find even the slightest misprint they reject the whole consignment. This routine helps us to ensure that each box that you get from us fulfills our quality assurance checklist. At Packim, we are committed to giving businesses the maximum return on their investment and that is why we offer custom front cut out display tray at wholesale prices. Buying bulk front cut out display tray is always recommended because it brings your per-unit cost down. So, when are you getting your front cut out cheap tray? We also offer other trays such as pop counter display trays.Ordering Custom Front Cut Out Tray For Display Is Not A Problem Anymore With Packlim

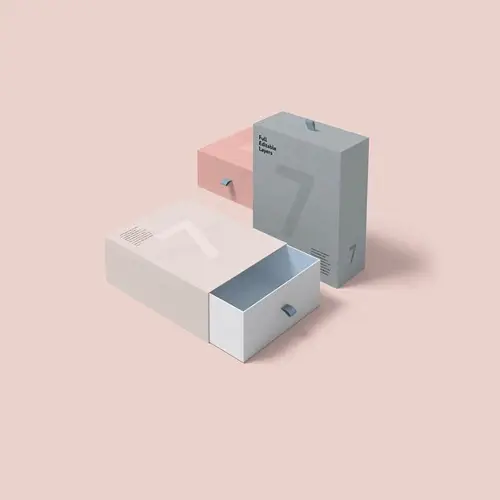

It’s like a breeze with Packlim to order cut out display tray wholesale. We help you to get your dream packaging trays with a smooth and easy ordering process. These accessible steps can provide a bridge to reach the point where you can satisfy your packaging concerns. Step 1 Choose Length, Width, and Height ( Inner Size | Outer Size ) Step 2 Choose Material Type- SBS Paperboard | Off-White Inside | White Outside

- 1 Side Coated Paperboard | Shiny White Outside | Grey Inside

- 2 Side Coated Paperboard | White Inside | White Outside

- Brown Card | Brown Inside| Brown Outside

- E-Flute Single Wall Corrugated Board

- E-Flute Single Wall Corrugated Board

- 150 GSM or 10 PT

- 200 GSM or 12 PT

- 250 GSM or 14 PT

- 300 GSM or 16 PT

- 350 GSM or 18 PT

- 400 GSM or 20 PT

- 500 GSM or 28 PT

- 600 GSM or 32 PT

- 700 GSM or 36 PT

- 350 GSM or 18 PT

- 400 GSM or 20 PT

- 1 Color Printing

- 2 Color Printing

- Full-Color Printing

- Spot Colors

- Gloss Lamination

- Matte Lamination

- Gloss Water Based Varnish

- Matte Water Based Varnish

- UV Varnish

- Calendering Varnish

- Embossing

- Debossing

- Spot UV

- Hot Foiling

- Die Cut

Full Color Printing

Get the perfect blend (CMYK) inks and PMS up to 4 colors. Bespoke design with quality graphics. Sharp, permanent, and photorealistic printed details.

Inside & Outside Full Printing

Create high-quality and consistent print on both sides of your packaging paper. Full-color premium graphics printed on both the internal and external surfaces.

One Color Printing

Single ink color printed design. Creates a bold, minimalist, and aesthetic impression on the packaging. Frequently applied for logos and text-based designs.

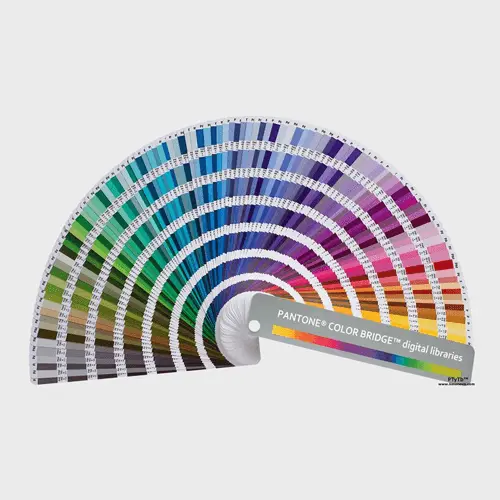

PMS Printing

Pantone Matching System confirms consistent color blending with the help of pre-mixed, standardized inks. Perfect for creating high-resolution printed design

Cardboard

The most commonly used sturdy and versatile packaging material. Perfect for custom boxes, packaging inserts, and displays. It is feasible to be coated or printed.

Corrugated

Known as multi-layered cardboard having fluted inner layers sandwiched between two layers of cardboard. Has more strength and is ideal for shipping and bulk packaging.

Kraft material

Known as a natural paper with a raw earthy aesthetic. Frequently applied for eco-friendly packaging boxes and kraft-made paper bags. It is cost-effective and easy to use

Rigid box

Ideal for luxury packaging option. Defined as a thick, sturdy cardboard, offering premium protection and a more appealing look than ordinary cardboard. Ideal for packaging costly items.

Oil Based Inks

Highly absorbable and water-resistant. Such things are expert In producing a rich, vibrant finish in the printed design. Ideal for the designs that have to be prolonged.

Water-Based Inks

Water-based inks are eco-friendly heroes. They are perfect for design with vibrant colors soaked into fabrics for soft. These inks swap harsh solvents for H2O.

Pantone

This is used in the Pantone Matching System as pre-mixed inks. Ideal for consistent color across different printing presses. It can make prints covering a wide range of colors and finishes.

Fluorescent Inks

It is a collection of vibrant inks that glow under UV light. It is easily aligned with the design and is perfect for creating bold, attention-grabbing designs. Gives a luxury touch in the design.

Holographic

Adds a luxurious touch to the packaging by creating a rainbow-like, reflective effect. It creates a magic effect on the printed surface of the packaging box.

Metallic Paper

Make the packaging get a sheen and shimmering look. It is supported by various colors and has the main purpose of an elegant and premium look.

Natural Brown Kraft

Naturally occurring and untreated brown Kraft paper. Best for creating a rustic, organic aesthetic in the custom product packaging. Accelerate your branding.

White Kraft

Bleached Kraft paper. A premium white shade it has. One of the highest quality and ideal packaging materials. Offer a natural, clean, and versatile base for printing and design

Box Board E Flute

It belongs to the class of lightweight cardboard. Commonly used for folding cartons. Can be used as an ideal package material for desired strength and printability.

Crystal White E-Flute

This type of corrugated cardboard E-Flute box board with a premium bright white finish. Can be a perfect packaging option when high-quality printing is the final choice.

Kraft E-Flute card material

E-Flute board Is one of the most eco-friendly packaging options. It is made from recycled Kraft paper. Can be ideal for bulk product packaging with the desired level of durability.

SBS E-Flute

Highest-quality Solid Bleached Sulfate (SBS) E-Flute board has premium strength. It has printability and feasibility to assemble. Offer better and premium packaging.

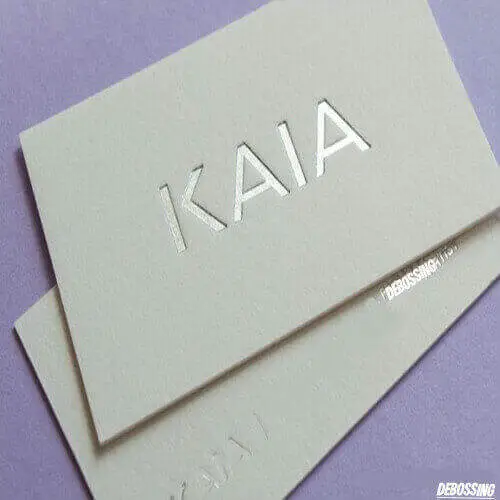

Debossing

Text embedded or sunken in the packaging texture. It creates a more engaging and performing design printed on the box. Create a unique and sharp impression making texture elegant.

Embossing

Raised or bulging out text or design elements above the paper surface. Create a sensory effect and appeal to visit more strongly. Reflected the true branding power.

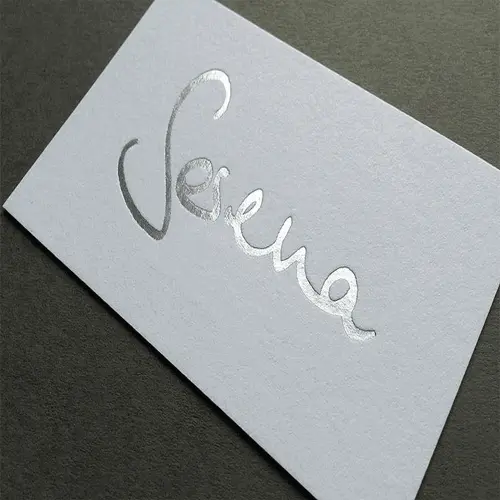

Foil stamping

A luxurious and premium-looking design requires a metallic or colored foil layer. Most commonly gold and silver foil stampings are enough to create an eye-catching finish.

Window Patching

It enhances product visibility by being properly coordinated into packaging. Attract customers by revealing the secret features of the product before them. Enhance selling potential.

Anti Scratch Lamination

Protect both the printed design and information from being scratched and getting abrasions. As a protective guard on the packaging surface. best for premium packaging

Spot UV Material

This creates a highlighting effect with the help of a glossy UV coating to specific areas in the printed design. Grab the attention of the eyes glancing at the packaging box.

Soft Touch Coating

Add a sensory and velvety touch to the packaging surface. It is ideal for a smooth and luxurious feel. Often applicable to the premium product packaging.

Silk Lamination Cards

It is aimed at a premium soft and slight sheen effect on the surface of the box. Easily applicable for premium cards and invitations. Creates an imperial look.

Matt Varnish

It is pasted on the box surface to create a classic, understated look. It subdues the shine of the printed design. It has a magical impact on the overall box appearance.

Gloss Varnish

It makes the product packaging valuable by enhancing the design of the paper. It makes the printed design more vibrant and has an eye-catching appearance.

Lamination

It is applied as the waterproof protective layer to paper, enhancing the durability and water resistance of the packaging. Add some extra value to the printed design.

Matt Lamination

It forms a protective layer over the packaging with a matte finish. It preserves all the features of paper’s natural texture giving the extra shining effect to the design.

Gloss Lamination

Make your packaging shine with a glossy finish which is a protective layer applied to the surface. It strengthens and enhances the efficacy and vibrancy of colors.

Aqueous Coating Boxes

Most frequently applied water-resistant layer with a subtle sheen. It is one of the most eco-friendly lamination options. Empower the printed design with a waterproof action.

Frequently Asked Questions

Yes, we allow all our clients who do not have a pre-box design to get their unique and trendy box design ready with us without any additional charges.

We use various materials for the customization of packaging boxes. We have cardboard, kraft, corrugated, and rigid stock that are used to create durable, luxury, and sustainable boxes for various products.

Our standard turnaround time is 09-12 working days all across the USA. But some complex and bulk orders of custom packaging boxes can take more days.

You can purchase at least 100 boxes in one order from us. If you purchase more than 1000 boxes, we will offer you a 40% discount.

We offer free shipping of custom boxes all across the USA, regardless of whether your order is small or bulk

Yes! We manufacture our boxes with recyclable and biodegradable materials, including kraft, cardboard, corrugated, and rigid.